Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

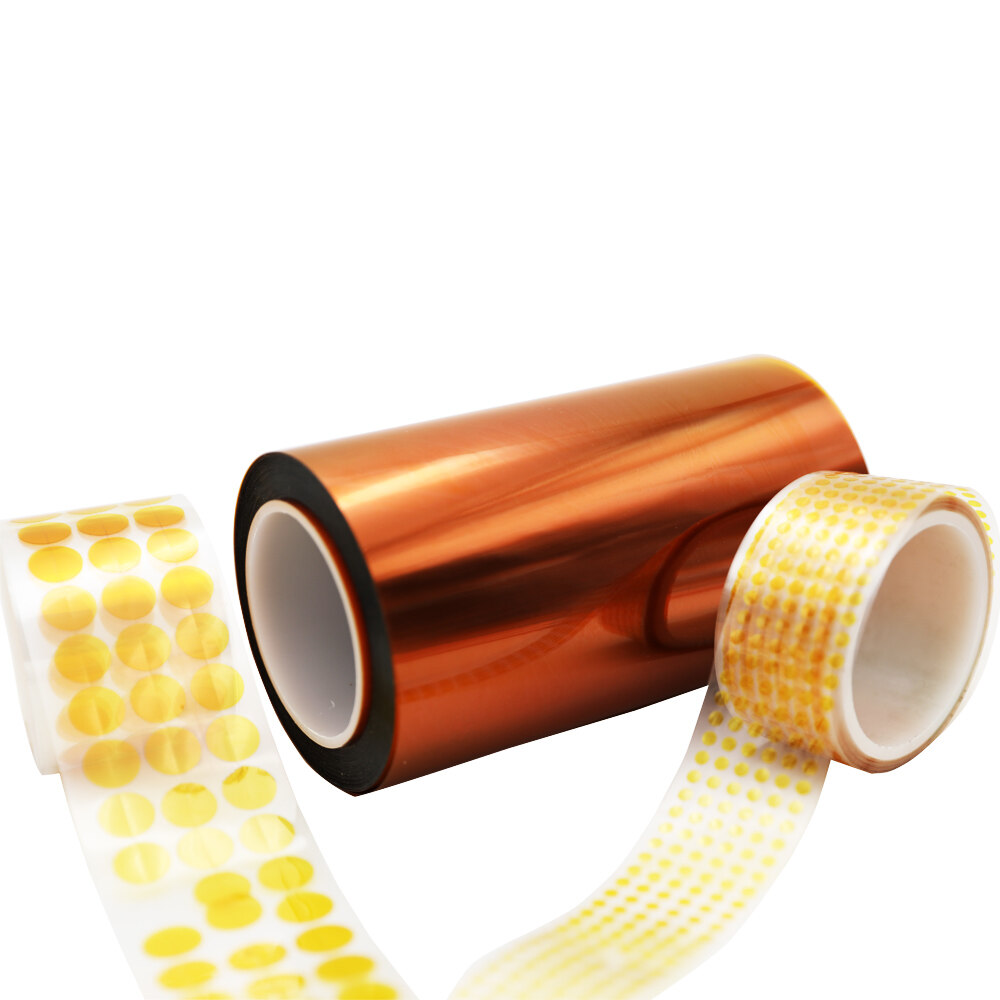

POLYIMIDE MASKING DISCS

Polyimide die-cuts are also named polyimide masking discs. It is made from polyimide film (gold film), with good viscosity and adhesion, acid and alkali resistance, high-temperature resistance, solvent resistance, no tin penetration, no glue residue, self-adhesive sealing, electrical insulation (class H), radiation resistance, and other characteristics.

The polyimide die-cut is with polyimide film as the basic carrier coated with pressure-sensitive silicone adhesive and later combined with fluorine release liner or release paper. The tape can be removed from the liner very easily and lightly after die-cutting. We may make different shapes and sizes according to the customers' requirements. With its excellent temperature resistance, easy removal, and good adhesion, it has been widely used for masking and protection of electrical parts.

Product Parameters

1. Color: amber

2. Backing material: polyimide film, fluorine release film

3. Adhesive: pressure-sensitive silicone adhesive

4. Thickness: 0.04mm-0.18mm

5. Length: customized

6. Width: within 1020mm or die-cutting according to customer requirements

7. Temperature resistance: 260℃

8. Adhesion: 4N/25mm-8N/25mm

9. Voltage resistance: 5kv-12kv

The Features Of Polyimide Die-cuts

1. High-temperature resistance

High-temperature resistance is a necessary feature of industrial tape because in the industrial environment, there are many high-temperature environments. If it cannot achieve good high-temperature resistance, it will naturally not be able to achieve the purpose of use, not just a single The same is true for the tapes used in daily life. There are also many high-temperature environments where tapes are used, so such tapes are also needed.

2..Radiation resistant

Radiation is also one of the most important features of polyimide film, whether it is for the protection of industrial originals or for the environmental protection requirements of the human body, it must also meet such requirements.

3. Resistant to chemical components

In the industrial environment, many of polyimide die-cuts are used in a chemical environment. It naturally must meet this requirement.

The Applications Of Polyimide Die-cuts

1. The electronics industry, fix lithium battery's anode and protect adhesion away from the influence of electrolyte.

2. SMT tin stove, Lithium battery, motors, coils, capacitors, and variable frequency power supply

3. Masking parts for powder coat paint

4. PCB, SMT masking protection in electronics

5. Masking edges of overlap seams in the metal bonding process where excess adhesive flows onto tape. Minimizes clean-up on tape removal.

6. Excellent solvent and moisture resistance.

7. Insulation protection for electrical devices like transformers and capacitor

8. Frequency conversion power supply in the electronics industry. Also use as the perfect heat-resistance ribbon on 3d printing, powder coating, etc.

For more information about POLYIMIDE DIE-CUTS, please kindly contact us at any time, we are glad to answer for you. If you want to find a partner, hope that we will be your best choice.